Renson International offers the most comprehensive range of high-quality and performance Engine Valves in the industry. Engine valves is one of the most critical and precision part in any of the Internal Combustion engine. It is manufactured with electrically actuated upsetting and hydraulically forged into desired shape. Then with the help of precision machining it is carved into a best performing finished products.

Engine Valves undergoes into rigorous testing environment to meet O.E standard during entire manufacturing cycle and ensures highly reliable, durability and our quality principles for High Performance Engine Valves.

With over more than 40 + years of expertise in manufacturing and supplying quality Engine Valves, Renson International has been competent and preferred supplier all over the world. Our portfolio includes 2500+ designs of Valves from more than 150+ brands of engines served to our customer. We offer Engine Valves made from wide range of high graded materials from Martensitic steels, Austenitic steels and super alloys like Inconel steel , Nimonic steel.

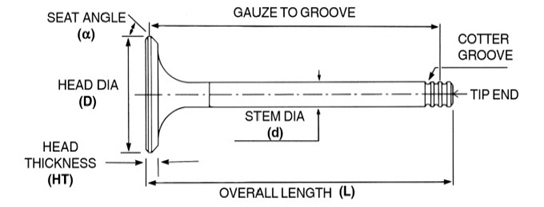

Valve Sizes

-

STEM DIA

4.50mm to 13.00mm

-

HEAD DIA

17.00mm to 60.00mm

-

OVERALL LENGTH

60.00mm to 300.00mm

Material Chart

Most commonly used Martensitic and Austenitic Steel grade for Manufacturing Engine Valves are listed below,

| SAE |

BS |

JIS |

DIN |

Tensile N/MM2 |

C |

Si |

Mn |

Ni |

Cr |

Mo |

N |

| SIL1 |

EN 52 |

SUH 1 |

1.4718 |

900-1100 |

0.40-0.50 |

3.00-3.50 |

0.60-MAX |

0.60-MAX |

7.50-9.50 |

-- |

-- |

| -- |

-- |

SUH 3 |

1.4731 |

880 |

0.35-0.45 |

1.80-2.50 |

0.60-MAX |

0.60-MAX |

10.00-12.00 |

0.70-1.30 |

-- |

| -- |

-- |

SUH 11 |

-- |

900-1100 |

0.45-0.55 |

1.00-2.00 |

0.60-MAX |

0.60-MAX |

7.50-9.50 |

-- |

-- |

| EV-12 |

21-2N |

-- |

1.4875 |

900-1150 |

0.50-0.60 |

0.08-0.25 |

7.00-9.50 |

1.50-2.75 |

19.25-21.50 |

-- |

0.20-0.40 |

| EV-8 |

21-4N |

SUH 35 |

1.4871 |

900-1150 |

0.48-0.58 |

0.35 MAX |

8.00-10.00 |

3.25-4.50 |

20.0-22.50 |

-- |

0.35-0.50 |

| EV-15 |

23-8N |

-- |

1.4866 |

850 |

0.28-0.38 |

0.50-1.00 |

1.50-3.50 |

7.00-9.50 |

22.00-24.00 |

-- |

0.25-0.40 |

| EV-4 |

21-12N |

SUH 37 |

-- |

800 |

0.15-0.25 |

1.00 MAX |

1.00-1.60 |

10.00-12.00 |

20.50-22.50 |

-- |

0.15-0.35 |

| INCONEL-751 |

|

|

0.10 MAX |

0.50 MAX |

1.00 MAX |

AVG |

14.0-17.0 |

Ti/AL 2.2/1.0 |

FE 7.0 |

| NIMONIC-80A |

|

|

0.10 MAX |

1.00 MAX |

1.00 MAX |

AVG |

18.0-21.0 |

Ti/AL 2.0/1.5 |

FE/CO 5.0/2.0 MAX |

Stellite Grade

Commonly used Stellite grade for Seat hardening and Tip Hardening are as follows,

| Stellite Grade |

C |

CR |

Ni |

W |

FE |

CO |

Hardness (HRC) |

| STELLITE #1 |

2.5 |

30.0 |

3.0 MAX |

12.0 |

3.0 MAX |

BAL |

50/54 |

| STELLITE #6 |

1.00 |

28.0 |

3.0 MAX |

4.0 |

3.0 MAX |

BAL |

40/44 |

| STELLITE #12 |

1.35 |

29.0 |

3.0 MAX |

8.0 |

2.0 MAX |

BAL |

45/47 |

| STELLITE #32 |

1.80 |

26.0 |

10.0 |

12.0 |

2.0 MAX |

BAL |

25/35 |